- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

EnglishThe self-cleaning process of the automatic brush self-cleaning filter is started by monitoring the pressure difference between the inlet and outlet of the filter at a time. Usually, the preset value of the pressure difference switch is 0.04MPa. The filter has the advantages of continuous filtration, easy maintenance and reliable operation, so it is widely used in many industrial areas.

| Availability: | |

|---|---|

| Quantity: | |

BTDS

BEITE

The automatic brush self-cleaning filter mainly includes: housing, filter cartridge (filtering dirt), cleaning mechanism (including cleaning brush, filter screen), controller (collecting and comparing differential pressure signals, outputting control signals), motor (receiving control signals, providing cleaning The power required by the mechanism), and electric ball valve (receive control signal, discharge dirt).

Technical Parameters

A single maximum flow capacity is up to 4000m3/h

Set Differential Pressure Range: 0~69KPa

Working Pressure: ≤2.5MPa(customized is available)

Working Temperature ≤150ºC

Power Pupply: 380V/50 Hz (Customized is available)

Cleaning Method: Brush Type

Filtration Accuracy: 4-25meash/in

Motor Power: 180~750W

Working Principle

When the water flows through the filter, the impurities in the water are intercepted by the filter, and the accumulated impurities on the surface of the filter increase to make the pressure difference reach the set value. The differential pressure switch sends out a signal, the transmission motor starts, the sewage valve opens, and the impurities deposited in the filter Impurities are brushed down by the rotating brush and discharged from the sewage outlet. The whole scrubbing and sewage discharge process requires no personnel operation and no downtime. At the same time, the equipment also has the functions of regular cleaning and sewage discharge and manual cleaning and sewage discharge.

Features

1. Fully Automatic Operation: Once set the data, it can automatically detect the pressure difference between the inlet and outlet, automatically clean the filter screen, and automatically discharge sewage.

2. Accurate and Reliable: Imported international brand differential pressure controller, accurate measurement and reliable control.

3. Reasonable Configuration: The electric butterfly valve is used as the sewage valve to solve the phenomenon of loose valve closing and unstable quality, and avoid the influence of too fast opening speed of the solenoid valve on the system pressure.

4. High Degree of Automation: Provide standard communication interface, can be connected to any monitoring network.

5. Precision production, long service life.

6. Multiple Self-protection: The controller adopts automatic and manual dual settings.

Model Selection

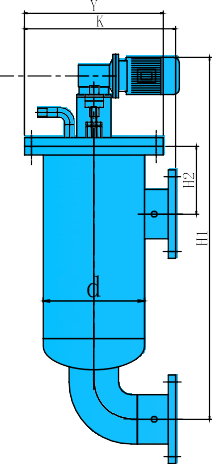

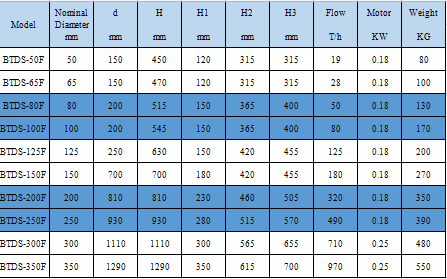

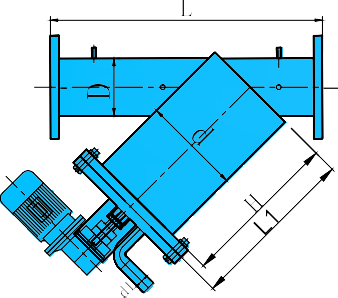

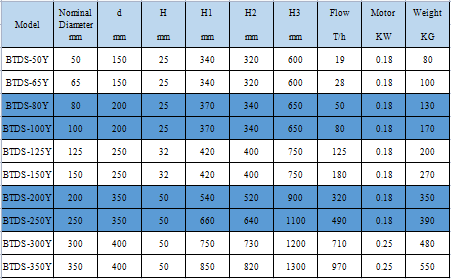

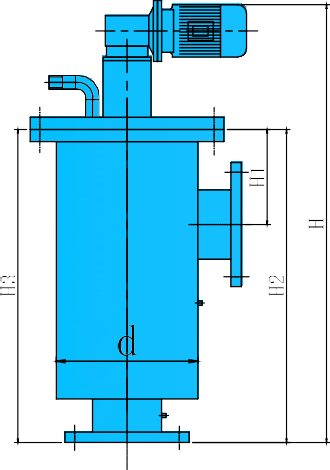

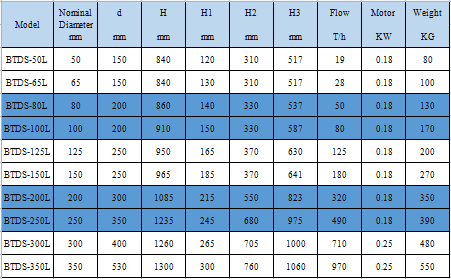

1. Dimension table of BTDS-F brush type self-cleaning filter

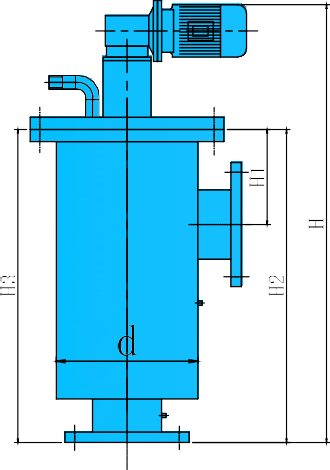

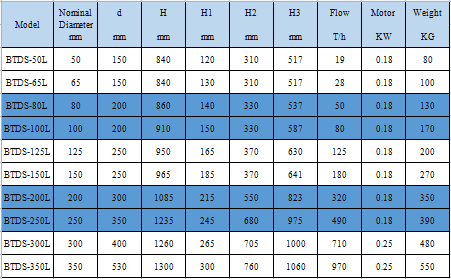

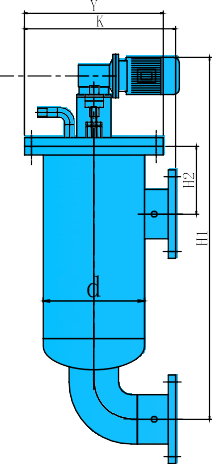

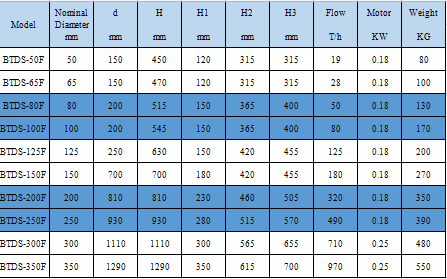

2. Dimension table of BTDS-L brush type self-cleaning filter

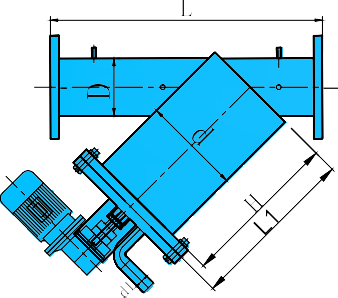

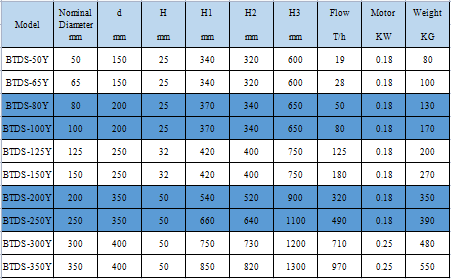

3. Dimension table of BTDS-Y brush type self-cleaning filter

Application

Widely used in drinking water treatment, building circulating water treatment, industrial circulating water treatment, sewage treatment, mining industry water treatment, golf course water treatment and other fields.

The automatic brush self-cleaning filter mainly includes: housing, filter cartridge (filtering dirt), cleaning mechanism (including cleaning brush, filter screen), controller (collecting and comparing differential pressure signals, outputting control signals), motor (receiving control signals, providing cleaning The power required by the mechanism), and electric ball valve (receive control signal, discharge dirt).

Technical Parameters

A single maximum flow capacity is up to 4000m3/h

Set Differential Pressure Range: 0~69KPa

Working Pressure: ≤2.5MPa(customized is available)

Working Temperature ≤150ºC

Power Pupply: 380V/50 Hz (Customized is available)

Cleaning Method: Brush Type

Filtration Accuracy: 4-25meash/in

Motor Power: 180~750W

Working Principle

When the water flows through the filter, the impurities in the water are intercepted by the filter, and the accumulated impurities on the surface of the filter increase to make the pressure difference reach the set value. The differential pressure switch sends out a signal, the transmission motor starts, the sewage valve opens, and the impurities deposited in the filter Impurities are brushed down by the rotating brush and discharged from the sewage outlet. The whole scrubbing and sewage discharge process requires no personnel operation and no downtime. At the same time, the equipment also has the functions of regular cleaning and sewage discharge and manual cleaning and sewage discharge.

Features

1. Fully Automatic Operation: Once set the data, it can automatically detect the pressure difference between the inlet and outlet, automatically clean the filter screen, and automatically discharge sewage.

2. Accurate and Reliable: Imported international brand differential pressure controller, accurate measurement and reliable control.

3. Reasonable Configuration: The electric butterfly valve is used as the sewage valve to solve the phenomenon of loose valve closing and unstable quality, and avoid the influence of too fast opening speed of the solenoid valve on the system pressure.

4. High Degree of Automation: Provide standard communication interface, can be connected to any monitoring network.

5. Precision production, long service life.

6. Multiple Self-protection: The controller adopts automatic and manual dual settings.

Model Selection

1. Dimension table of BTDS-F brush type self-cleaning filter

2. Dimension table of BTDS-L brush type self-cleaning filter

3. Dimension table of BTDS-Y brush type self-cleaning filter

Application

Widely used in drinking water treatment, building circulating water treatment, industrial circulating water treatment, sewage treatment, mining industry water treatment, golf course water treatment and other fields.