- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English| Availability: | |

|---|---|

| Quantity: | |

BTDS-Y

Nanjing Beite

Working Principle

After the water filter is connected to the pipeline system, the water enters the water filter from the lower water inlet, and the water after filtering the sundries flows out from the water outlet. On the core, when it accumulates to a certain amount, it will cause a certain pressure difference between the water inlet and the water outlet. When the water pressure difference between the inlet pressure gauge and the outlet pressure gauge of the filter increases to the specified value (the pressure difference is different for different filter diameters, generally 0.15Mpa), open the drain valve and put it into operation, and the water flow is attached to the inner wall of the mesh core. The impurities and dirt on the filter are backwashed, and the attachments are discharged from the filter screen. When the internal and external pressure difference returns to normal, the sewage valve is closed to complete the process of filtering and sewage discharge.

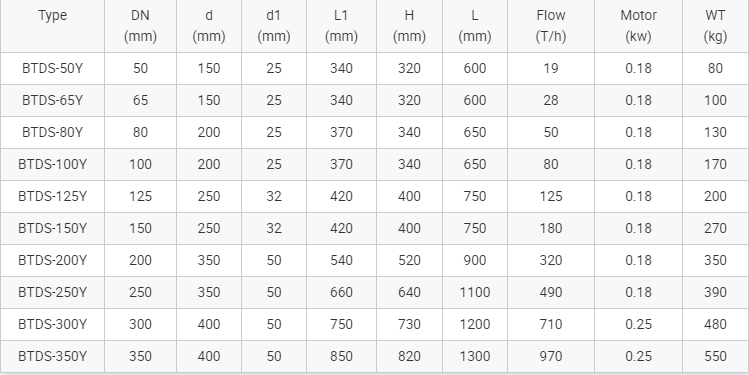

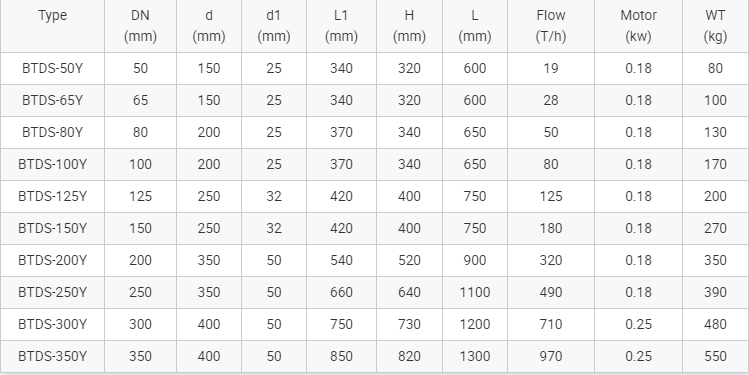

Technical Parameters

Work pressure: ≤2.5Mpa

Operating temperature:≤150°C

Cleaning time: set arbitrarily

Drag loss: 2.0-8.0KPa

Set differential pressure range:0-69KPa

Motor Power:180-750W

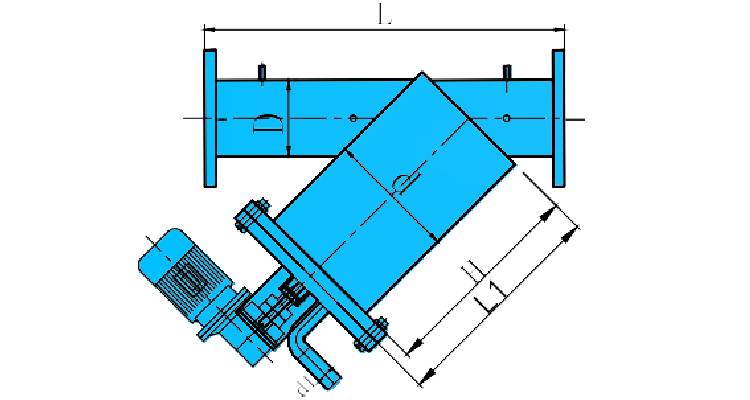

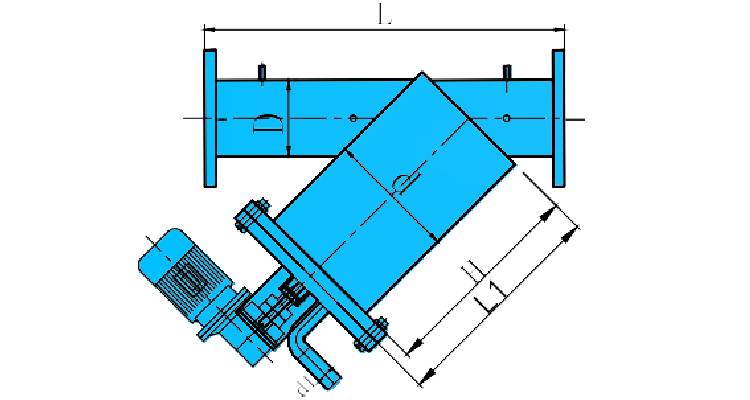

Appearance parameters

Features

1. The filtration accuracy can be selected from 50 to 1000 μm, the filtration area is large, and the dirt holding capacity is high. Users can customize it according to the actual working conditions.

2. The cleaning method is simple, and automatic sewage filtration can be realized.

3. It has the characteristics of uninterrupted water supply and no bypass during cleaning and sewage discharge, and the cleaning time is short, and the water consumption of sewage discharge is less, which does not exceed 1% of the total flow.

4. Strong maintainability, easy installation and disassembly.

5. The connection method with the user's pipeline is flange connection, and the flange adopts the national standard flange, which has strong versatility.

Product scope

1. Air-conditioning and HVAC system: effectively reduce suspended solids and turbidity, solve system blockage problems such as condensers and coolers, maximize the effect of descaling equipment and chemicals, and improve system operating efficiency;

2. Iron and steel: used for water treatment and filtration in raw material yards, sintering and pelletizing plants, cooling water filtration in blast furnaces, rolling mills, continuous casting machines and other systems, and impurity filtration in high-pressure water phosphorus removal systems;

3. Automobile manufacturing: coating production line, cooling circulating water system, widely used in the water treatment process of automobile, tractor, motorcycle and engine manufacturing;

4. Power plant: used for the precision pretreatment part of the high-purity water preparation of the boiler of the power plant, and the filtration of the cooling circulating water and sealing water of the generator;

5. Petrochemical industry: Side filtration treatment in the circulating water field can be used for single-machine or multi-machine parallel main treatment to replace filter material filtration, reduce filter material filtration load, avoid a large amount of washing water consumption, and save costs;

6. Agricultural gardens and papermaking: in systems with nozzles and nozzles, equipment blockage and wear caused by impurities should be reduced, so it is necessary to choose high-precision, high-automation filtration products;

7. Water supply and sewage treatment: used in the pretreatment system to improve the operating efficiency of the system;

8. Mine: Filter underground spray water to ensure the system works normally.

Working Principle

After the water filter is connected to the pipeline system, the water enters the water filter from the lower water inlet, and the water after filtering the sundries flows out from the water outlet. On the core, when it accumulates to a certain amount, it will cause a certain pressure difference between the water inlet and the water outlet. When the water pressure difference between the inlet pressure gauge and the outlet pressure gauge of the filter increases to the specified value (the pressure difference is different for different filter diameters, generally 0.15Mpa), open the drain valve and put it into operation, and the water flow is attached to the inner wall of the mesh core. The impurities and dirt on the filter are backwashed, and the attachments are discharged from the filter screen. When the internal and external pressure difference returns to normal, the sewage valve is closed to complete the process of filtering and sewage discharge.

Technical Parameters

Work pressure: ≤2.5Mpa

Operating temperature:≤150°C

Cleaning time: set arbitrarily

Drag loss: 2.0-8.0KPa

Set differential pressure range:0-69KPa

Motor Power:180-750W

Appearance parameters

Features

1. The filtration accuracy can be selected from 50 to 1000 μm, the filtration area is large, and the dirt holding capacity is high. Users can customize it according to the actual working conditions.

2. The cleaning method is simple, and automatic sewage filtration can be realized.

3. It has the characteristics of uninterrupted water supply and no bypass during cleaning and sewage discharge, and the cleaning time is short, and the water consumption of sewage discharge is less, which does not exceed 1% of the total flow.

4. Strong maintainability, easy installation and disassembly.

5. The connection method with the user's pipeline is flange connection, and the flange adopts the national standard flange, which has strong versatility.

Product scope

1. Air-conditioning and HVAC system: effectively reduce suspended solids and turbidity, solve system blockage problems such as condensers and coolers, maximize the effect of descaling equipment and chemicals, and improve system operating efficiency;

2. Iron and steel: used for water treatment and filtration in raw material yards, sintering and pelletizing plants, cooling water filtration in blast furnaces, rolling mills, continuous casting machines and other systems, and impurity filtration in high-pressure water phosphorus removal systems;

3. Automobile manufacturing: coating production line, cooling circulating water system, widely used in the water treatment process of automobile, tractor, motorcycle and engine manufacturing;

4. Power plant: used for the precision pretreatment part of the high-purity water preparation of the boiler of the power plant, and the filtration of the cooling circulating water and sealing water of the generator;

5. Petrochemical industry: Side filtration treatment in the circulating water field can be used for single-machine or multi-machine parallel main treatment to replace filter material filtration, reduce filter material filtration load, avoid a large amount of washing water consumption, and save costs;

6. Agricultural gardens and papermaking: in systems with nozzles and nozzles, equipment blockage and wear caused by impurities should be reduced, so it is necessary to choose high-precision, high-automation filtration products;

7. Water supply and sewage treatment: used in the pretreatment system to improve the operating efficiency of the system;

8. Mine: Filter underground spray water to ensure the system works normally.