- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English| Availability: | |

|---|---|

| Quantity: | |

BTDS

BEITE

Automatic brush self-cleaning filter is a widely used equipment in the water treatment industry. Its simple design and good performance enable the sewage to achieve a good filtering effect. Its main components are: motor, electric control box, control pipeline, main pipe assembly, filter element assembly, stainless steel brush, frame assembly, transmission shaft, inlet and outlet connecting flanges, etc.

Technical Parameters

A single maximum flow capacity is up to 4000m3/h

Set Differential Pressure Range: 0~69KPa

Working Pressure: ≤2.5MPa(customized is available)

Working Temperature ≤150ºC

Power Pupply: 380V/50 Hz (Customized is available)

Cleaning Method: Brush Type

Filtration Accuracy: 4-25meash/in

Motor Power: 180~750W

Filter Material

Housing: Carbon Steel or 304 Stainless Steel

Screen: 304 Stainless Steel

Cleaning Brush: Bristle Hair or Stainless Steel

Product Features

1. Automatic operation of self-cleaning filter adopts advanced automatic control method to realize complete automation;

2. The self-cleaning filter saves water and energy, and the power consumption is low;

3. Self-cleaning filter is easy to maintain, less daily maintenance, only regular inspection;

4. The self-cleaning filter is easy to install. Different installation methods can be selected according to different site conditions;

5. The self-cleaning filter continuously discharges water, and the flow does not stop during the cleaning process, which does not affect the normal operation of the system;

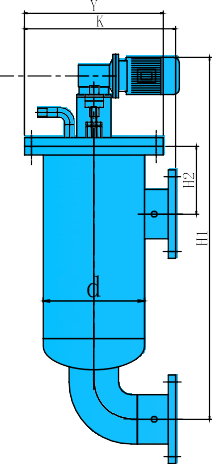

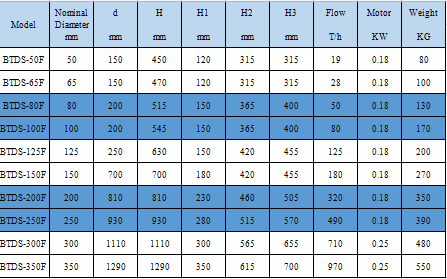

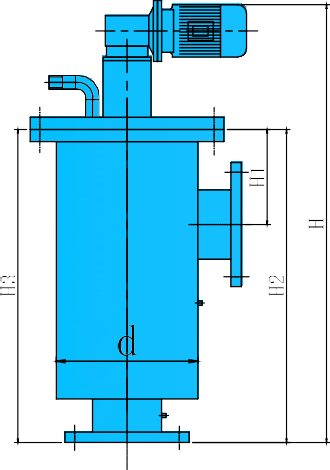

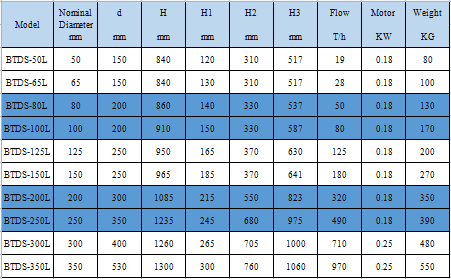

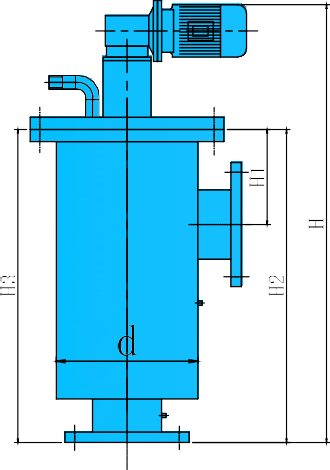

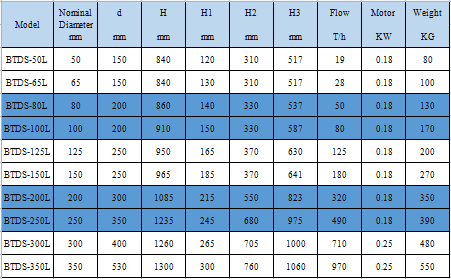

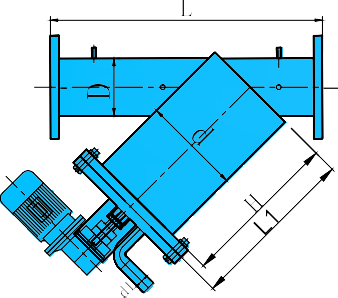

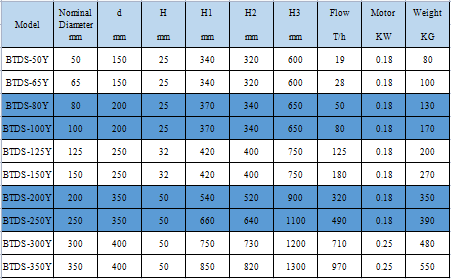

Shape Parameters

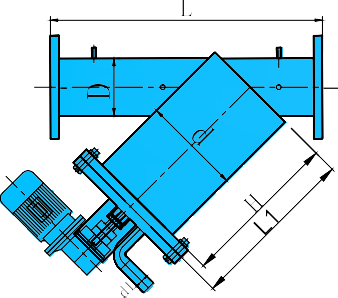

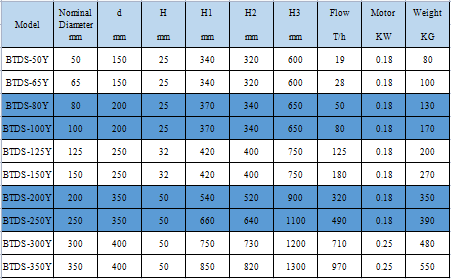

1. Dimension table of BTDS-F brush type self-cleaning filter

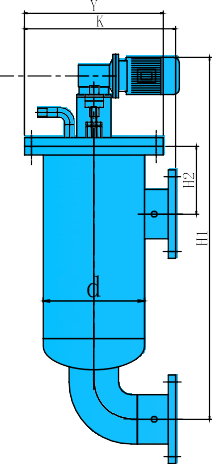

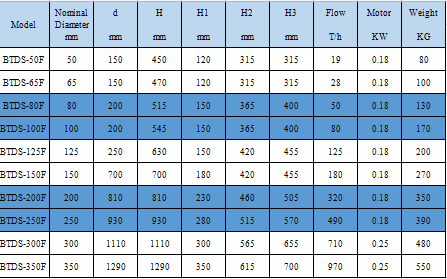

2. Dimension table of BTDS-L brush type self-cleaning filter

3. Dimension table of BTDS-Y brush type self-cleaning filter

Application

It is widely used in circulating or non-circulating cooling water systems, heat exchange systems, central air-conditioning systems, central heating systems, hot water boiler systems, etc., respectively used to protect cooling equipment, heat exchange devices, air conditioners, boilers, etc., rubber, paper, Textile, coal, food and other industries.

Automatic brush self-cleaning filter is a widely used equipment in the water treatment industry. Its simple design and good performance enable the sewage to achieve a good filtering effect. Its main components are: motor, electric control box, control pipeline, main pipe assembly, filter element assembly, stainless steel brush, frame assembly, transmission shaft, inlet and outlet connecting flanges, etc.

Technical Parameters

A single maximum flow capacity is up to 4000m3/h

Set Differential Pressure Range: 0~69KPa

Working Pressure: ≤2.5MPa(customized is available)

Working Temperature ≤150ºC

Power Pupply: 380V/50 Hz (Customized is available)

Cleaning Method: Brush Type

Filtration Accuracy: 4-25meash/in

Motor Power: 180~750W

Filter Material

Housing: Carbon Steel or 304 Stainless Steel

Screen: 304 Stainless Steel

Cleaning Brush: Bristle Hair or Stainless Steel

Product Features

1. Automatic operation of self-cleaning filter adopts advanced automatic control method to realize complete automation;

2. The self-cleaning filter saves water and energy, and the power consumption is low;

3. Self-cleaning filter is easy to maintain, less daily maintenance, only regular inspection;

4. The self-cleaning filter is easy to install. Different installation methods can be selected according to different site conditions;

5. The self-cleaning filter continuously discharges water, and the flow does not stop during the cleaning process, which does not affect the normal operation of the system;

Shape Parameters

1. Dimension table of BTDS-F brush type self-cleaning filter

2. Dimension table of BTDS-L brush type self-cleaning filter

3. Dimension table of BTDS-Y brush type self-cleaning filter

Application

It is widely used in circulating or non-circulating cooling water systems, heat exchange systems, central air-conditioning systems, central heating systems, hot water boiler systems, etc., respectively used to protect cooling equipment, heat exchange devices, air conditioners, boilers, etc., rubber, paper, Textile, coal, food and other industries.