- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English| Availability: | |

|---|---|

| Quantity: | |

BTDS-Y

BEITE

Working Principle

The automatic brush self-cleaning filter adopts high-strength filter screen, which has large processing capacity, long service life and high cleaning efficiency. The self-cleaning filter adopts pressure difference control and timing control to automatically clean the filter screen. When the pressure difference between the inlet and outlet of the filter reaches the set time, the electric control box sends out a signal to drive the motor to rotate, and at the same time, the drain valve opens. The impurities adsorbed on the filter screen are brushed off by the rotating steel brush and discharged from the drain valve with the water flow. When the pressure difference between the inlet and outlet of the filter returns to normal or the timer setting time is over, the motor will stop running and the electric blowdown valve will be closed. During the whole process, the material flows continuously, realizing continuous and automatic filtration. In addition, the self-cleaning filter is mainly composed of the equipment body (carbon steel and stainless steel are optional), filter screen, stainless steel brush, solenoid valve, motor, differential pressure controller, and sewage valve.

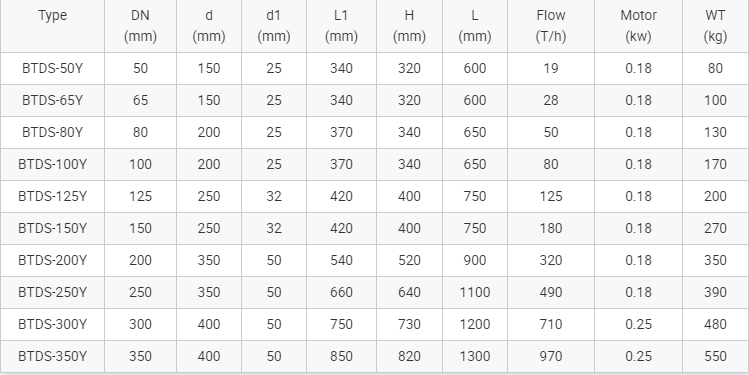

Technical Parameters

Work pressure: ≤2.5Mpa

Operating temperature:≤150°C

Cleaning time: set arbitrarily

Drag loss: 2.0-8.0KPa

Set differential pressure range:0-69KPa

Motor Power:180-750W

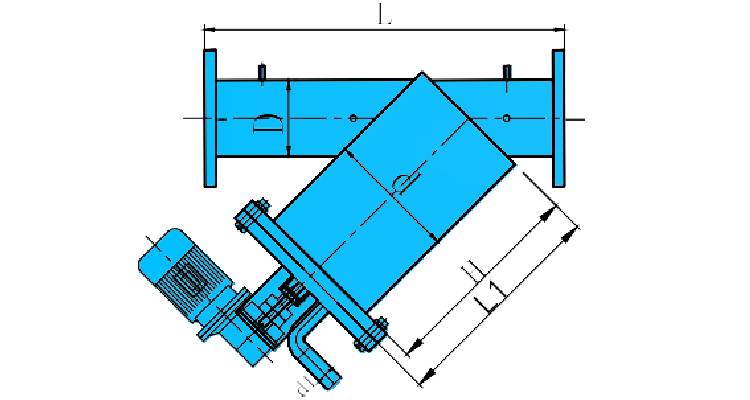

Appearance parameters

Product scope

The automatic brush cleaning filter is suitable for wastewater treatment, slag flushing water in steel mills, power plant process and cooling water, water intake links in papermaking processes, chemical production processes and irrigation systems, etc., to filter out various hard particles of 50-3500 microns in water quality particles to ensure the safe and reliable operation of the system.

Installation and use

The automatic brush self-cleaning filter can be installed horizontally or vertically according to the needs. When installing, it should be noted that the direction of the arrow on the housing must be consistent with the direction of water flow, and when installed vertically, the direction of water flow is required to flow from top to bottom.

Working Principle

The automatic brush self-cleaning filter adopts high-strength filter screen, which has large processing capacity, long service life and high cleaning efficiency. The self-cleaning filter adopts pressure difference control and timing control to automatically clean the filter screen. When the pressure difference between the inlet and outlet of the filter reaches the set time, the electric control box sends out a signal to drive the motor to rotate, and at the same time, the drain valve opens. The impurities adsorbed on the filter screen are brushed off by the rotating steel brush and discharged from the drain valve with the water flow. When the pressure difference between the inlet and outlet of the filter returns to normal or the timer setting time is over, the motor will stop running and the electric blowdown valve will be closed. During the whole process, the material flows continuously, realizing continuous and automatic filtration. In addition, the self-cleaning filter is mainly composed of the equipment body (carbon steel and stainless steel are optional), filter screen, stainless steel brush, solenoid valve, motor, differential pressure controller, and sewage valve.

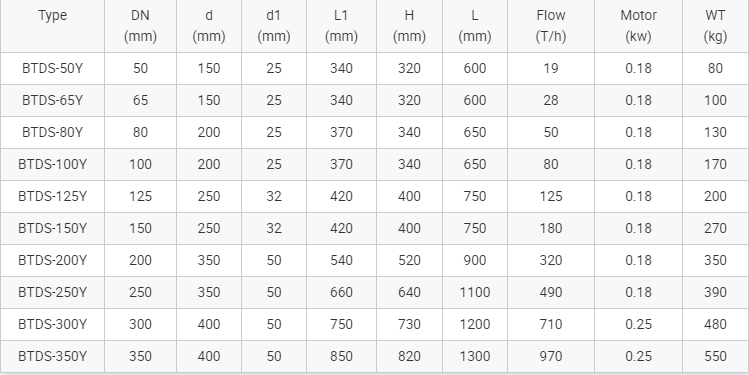

Technical Parameters

Work pressure: ≤2.5Mpa

Operating temperature:≤150°C

Cleaning time: set arbitrarily

Drag loss: 2.0-8.0KPa

Set differential pressure range:0-69KPa

Motor Power:180-750W

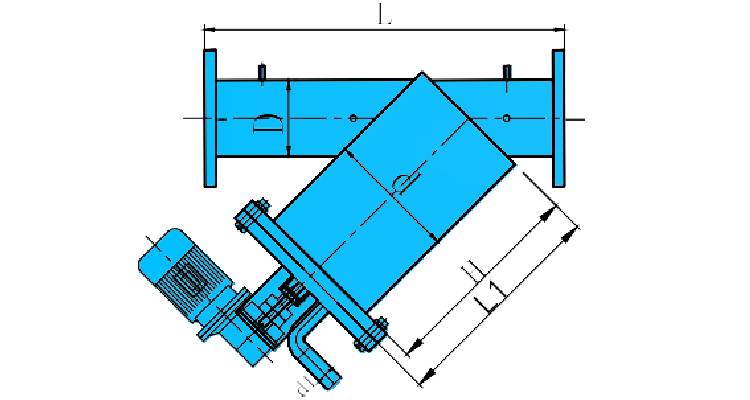

Appearance parameters

Product scope

The automatic brush cleaning filter is suitable for wastewater treatment, slag flushing water in steel mills, power plant process and cooling water, water intake links in papermaking processes, chemical production processes and irrigation systems, etc., to filter out various hard particles of 50-3500 microns in water quality particles to ensure the safe and reliable operation of the system.

Installation and use

The automatic brush self-cleaning filter can be installed horizontally or vertically according to the needs. When installing, it should be noted that the direction of the arrow on the housing must be consistent with the direction of water flow, and when installed vertically, the direction of water flow is required to flow from top to bottom.